POLAR LabelSystem DC-12 PLUS

Highly automated system for industrial label production

POLAR LabelSystem DC-12 PLUS is designed for highly automated inline production of bundled die-cut labels. The future-proof, new industrial control system enables remote maintenance and diagnostics, as well as integration into the digital workflow.

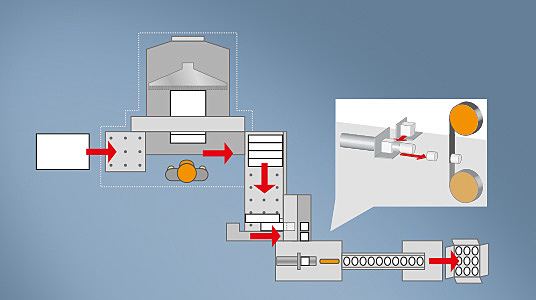

The workflow:

- The label material is pre-cut as strips inline or offline with a POLAR high-speed cutter

- The POLAR Autocut 25 PLUS automatic cutter takes over the strips and cuts two strips at a time into individual label packs

- The two labels are separated via the automatic label feed and fed individually in front of the die-cutting punch

- The stack is pressed by the punch through the cutting die of the POLAR System die-cutter DC (puncture principle) and receives its predefined shape

- The bundles of blanks are automatically pushed into the single-station bander BD PLUS and bundled together

- Industrial control system enables remote services as well as integration into the digital workflow

- Excellent performance of up to 1,440 bundles per 60 minutes with a minimum of manpower

- Capacitive colour display with touch function enables faster, more intuitive operation

- Job changeover at the touch of a button: minimum makeready times and format changeover in approx. 15 minutes thanks to automatic presettings

- Utmost cutting and die-cutting precision via fixing the material

- Automatic cutter Autocut 25 PLUS with alternate knife frame allows preparation off the machine

- System die-cutter DC PLUS is equipped with an alternate-frame system with patent positioning aid which allows preparation off the machine. An alternate frame in center position allows the easiest alignment to the right and left sides (patented). Size adjustment of gauge and feeder unit is carried out without any tools and synchronous via hand wheel (patented). For setting the register the stamping punch can be continuously extended millimeter by millimeter.

- On POLAR single-station bander BD PLUS size adjustment is motor-driven via central control display. This allows also a precision adjustment in automatic operation.

| Technical Data Single strip | Double strip | |

| Label size min. | 20 x 40 mm | 20 x 40 mm |

| Label size max. | 170 x 210 mm | 120 x 120 mm |

| Die-cut format min. | 16 x 36 mm | 16 x 36 mm |

| Die-cut format max. | 166 x 206 mm | 116 x 116 mm |

| Clamp opening min. | 35 mm | 35 mm |

| Clamp opening max. | 120 mm | 120 mm |

| Height of cutting die min. | 50 mm | 50 mm |

| Height of cutting die max. | 100 mm | 100 mm |

| Max. performance per minute | 18 bundles | 24 bundles |