POLAR Mohr, the Hofheim (Germany) based machine building and technology company, has developed an innovation for postpress finishing. The POLAR AirGo Jog processes entire layers fully automatically. An integrated blower unit is crucial for the systems’ success.

Driven by the vision of autonomous end-to-end print finishing, POLAR-Mohr (Hofheim) presents the AirGo Jog. The product innovation had its world premiere during the HD Innovation Week.

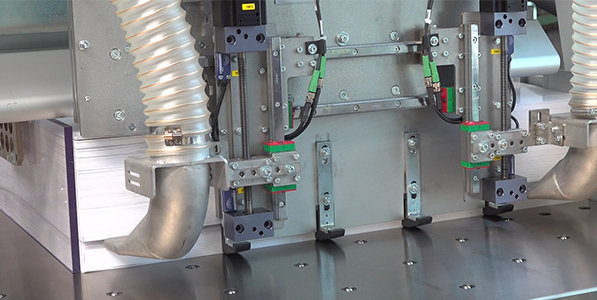

AirGo Jog automates the loading and jogging process. First, a Transomat loading unit takes an entire layer from a pallet and transports it into an automatic jogger. There the usual jogging process begins - with a decisive new component: a blower system. While jogging, two blower units blow air into the cutting layer to ensure a first-class jogging result. The jogged cutting layer is immediately ready for cutting.

With a cycle time of around 60 - 90 seconds for the autonomous processing of a complete cutting layer, the innovation from Hofheim is highly efficient. It can support every postpress department because retrofitting is possible on any cutting system. In addition to its intuitive operation via an all-new designed user interface, the AirGo Jog impresses with its attractive market price.

The name of the AirGo Jog is derived from the system’s essential elements: air and jogging. Not to be neglected is the significant improvement in ergonomics, as the heavy lifting of paper layers is no longer necessary. Therefore, AirGo is a wordplay, integrating er·go- into the product name.

POLAR AirGo Jog will be available from mid-2021.

October 2020